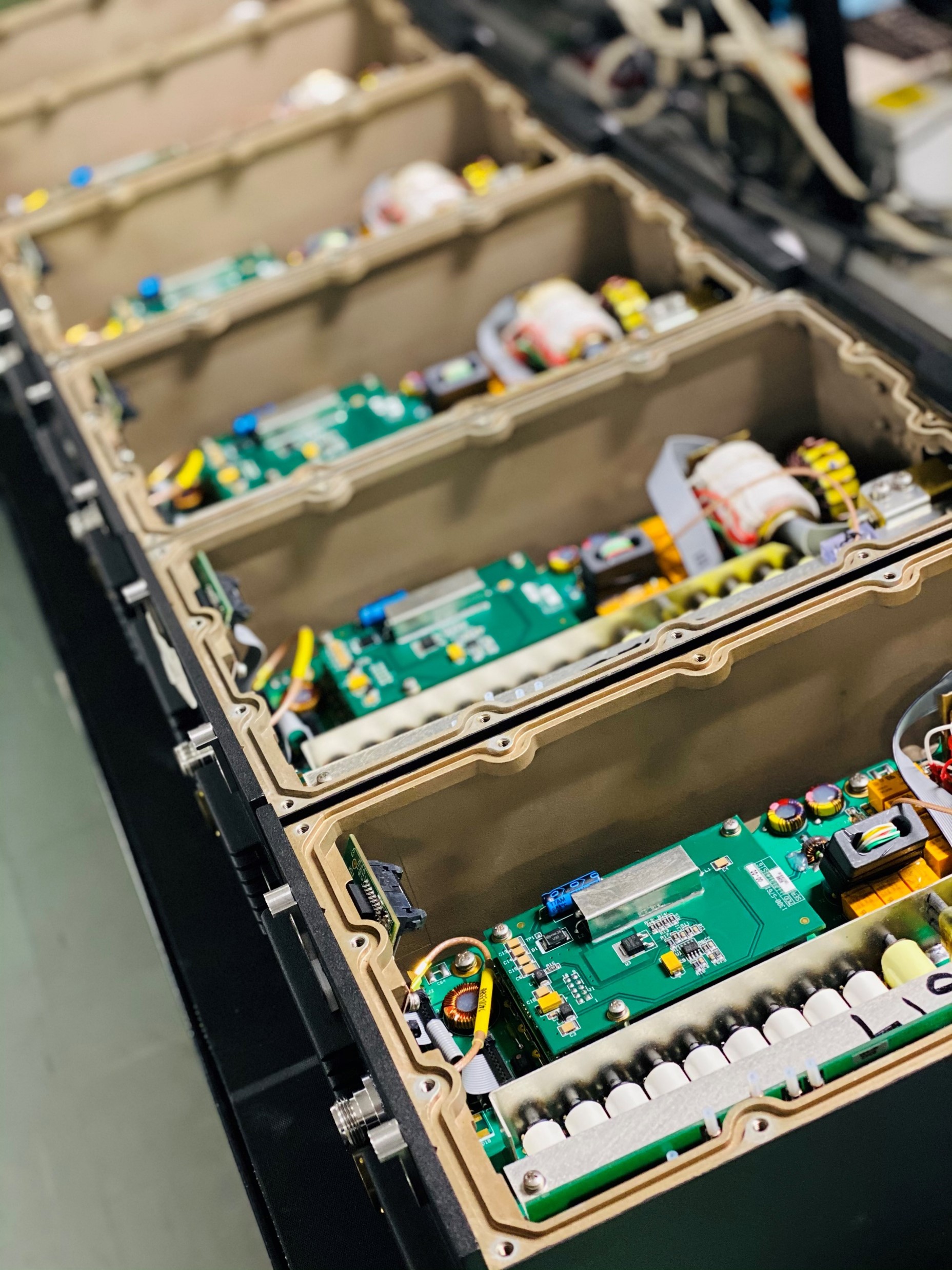

Payload Design and Manufacturing

Payload Design and ManufacturingOur Engineering Division does in-house design and development of custom-made Payload to fit any make and model drone, according client requirements.

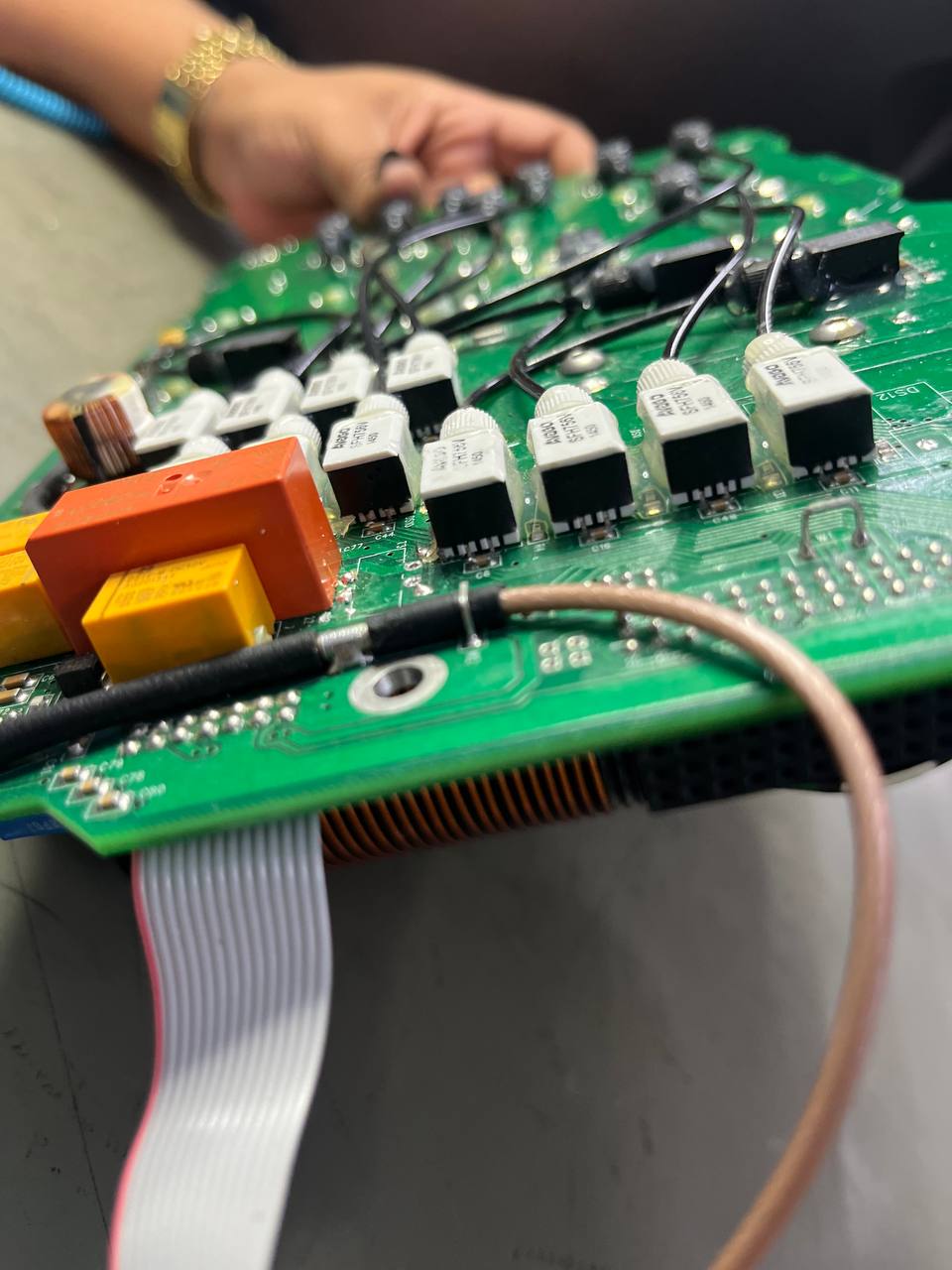

Printed Circuit Board Assembly (PCBA)

Printed Circuit Board Assembly (PCBA)Sovereignty Systems has a highly versatile, skilled (IPC-610-D Certified) and dedicated PCB Assembly team that works to produce a high-quality level of workmanship in hand soldering of SMD (from size 0402), fine pitch connectors and Through Hole components. We are able to offer both Leaded and RoHS compliant soldering of simple and complex PCB’s. Our Production facility is flexible enough to handle assemblies from single PCBA to mid-volume production. We manufacture according to the requirements of IPC Class 3.

Conformal Coating

Conformal CoatingOur very capable personnel are skilled in doing conformal coating which includes:

Coating on specific areas as requested by the client, avoiding connectors and no-go areas.

Coating of PCBA’s which is strictly done according to IPC-CC-830B/MIL-I-46058C standards.

Manufactured PCBA’s that are protected from damage such as contamination, salt spray, moisture, fungus, dust and corrosion that is caused by harsh or extreme environments.

Mechanical Assembly

Mechanical AssemblySovereignty Systems has extensive experience and tools in further integration of electronic PCBA’s and wiring into mechanical housings or systems. We are trained to comply with strict industry best practices when it comes to mechanical assembly. We have an in-house design team that can also design a suitable solution to package your product into a mechanical assembly.

Potting and Mechanical packaging

Potting and Mechanical packagingIn cases where a PCBA needs to be protected against extreme environmental conditions, potting or resin encapsulation is used to seal off the assembly. Typically, a resin or polyurethane with activator is used to encapsulate the product.

Sovereignty Systems is flexible and can adapt our processes for any client specification with regards to potting or encapsulation.

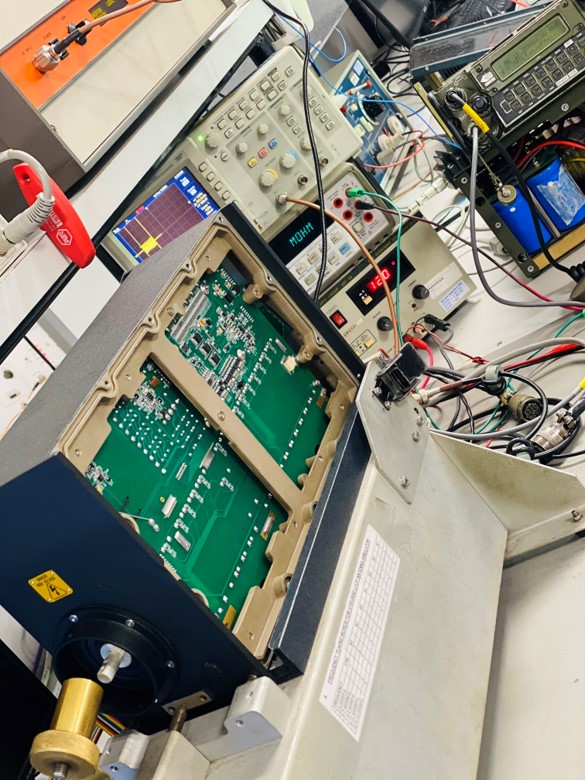

Test and Integration

Test and Integration Driven by our desire to increase efficiency and maintain product quality, Sovereignty Systems is continuously investing in our manufacturing facilities to ensure that we remain a major force in the South African and Global electronics market.

We have invested in systems that are technologically advanced, more efficient, easier to use and more able to test complex circuits.

The resulting lower number of defects increases the yield of good boards, reduces the amount of re‐work needed, increases the productivity of the PCB manufacturing area, and improves the quality of the end-product.

Full test solution development.

Radio frequency (RF) testing (up to 20GHz).

Product Industrialization

Product Industrialization Sovereignty Systems ensure that design information is correctly transferred to the production floor.

Depending on the complexity of the product, the following procedures may be implemented:

1. Obsolescence identification and management.

2. Design for manufacturing and assembly (DFMA) analysis and recommendations to minimise product cost and increase the yield by targeting the following primary drivers:

- Assembly time

- Component cost

- Assembly process

- Optimizing the PCB layout and specifications for the fabrication process

- Material selection

- Tooling strategies

- Testability and test coverage

Wiring, Looming and Harnessing

Wiring, Looming and HarnessingSovereignty Systems also manufactures looms, cables and wiring Harnesses.

Our manufacturing capabilities stretches over a variety of both military and commercial looms and cables, including stripping and crimping of coax cables.

We have a couple of standard applicators (crimping heads) procure additional crimping equipment as the need arises and where it is feasible to do so.

Quality Assurance

Quality AssuranceSovereignty Systems aims to exceed customer expectations and industry standards to create a unique quality system that ensures customer satisfaction and product reliability.

At Sovereignty Systems we take pride in having the highest possible standard of production, which is maintained through our strict quality control procedures.

These quality controls through multiple stages of our production process ensure constant testing and monitoring of our operation.

Sovereignty Systems continuously improves its client service and procedures to maintain or improve efficiency and quality.

We also offer a certification of the completed and tested product where required.

Work instructions are followed meticulously, ensuring that the quality of the product we produce, from beginning to end, is of the highest standard.